|

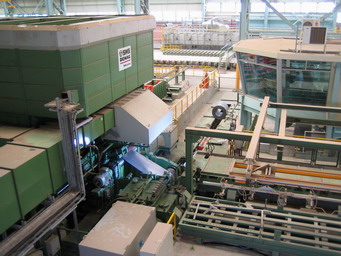

The state of the art Cold Rolling Mill, with an annual capacity of about 30,000 ton, consists of the following units:

1.Combined Single Stand Quarto CVC Reversing and Skin Pass Mill (SMS-DEMAG and Siemens) 2.High Convection Hydrogen Annealers (Batch Annealing, LOI) 3.Steel Service Center: inspection, slitting, cross cutting and side trimming (Pro/Eco)

1. Bright surface 2. The reversing cold rolling mill is equipped with automatic thickness (½ DIN EN tolerance), tension and flatness measuring and control, thus ensuring adherence to the tightest tolerances.

3. The recrystallization annealing process in the high convection hydrogen annealers guarantees stable and proper mechanical properties all over the entire strip width and length as well as high strip cleanliness. 4. The light skin passing (dry and wet) suppresses the yield-point elongation, with the result that during subsequent forming processes the sheet can be deformed without the occurrence of Lüders lines. In addition, the strip flatness is improved. 5. The production of cold rolled sheets is rounded off by the finishing stage. Depending on the order specifications, the strip is cut into sheet lengths, slit into slit strip, or recoiled and trimmed for delivery as wide strip. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||